Cold Hydraulic Presses for Engineered Wood Flooring Production

It is a well-known fact that the cold wood lamination process is the best possible way of ensuring the quality and durable bonding of wood using adhesives. With Deck Art cold hydraulic presses, you will achieve the finest quality of lamination of the flooring hardwood wear layer to the flooring core, and ensure a perfectly stable base for further processing with no effort. During the development of our presses, as flooring manufacturing experts, we have addressed all the common issues encountered by flooring manufacturers and, as a result, we proudly present to you our unique hydraulic presses dedicated to engineered wood flooring production.

Machine special features

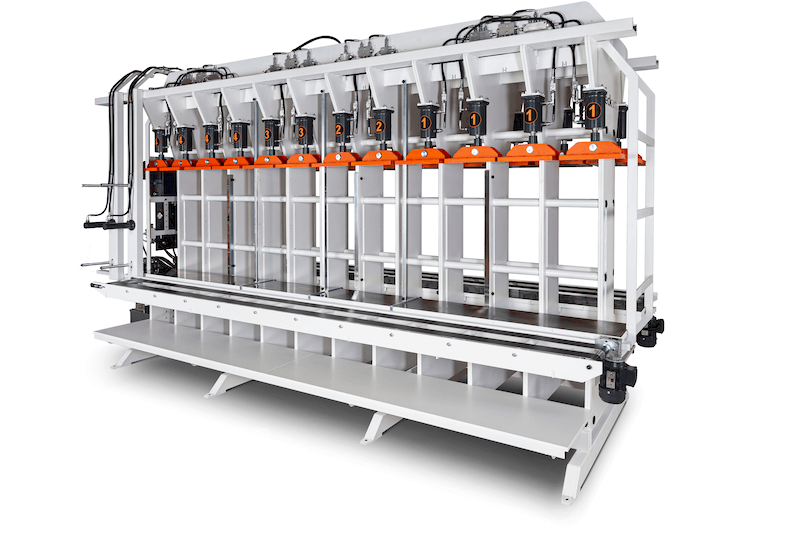

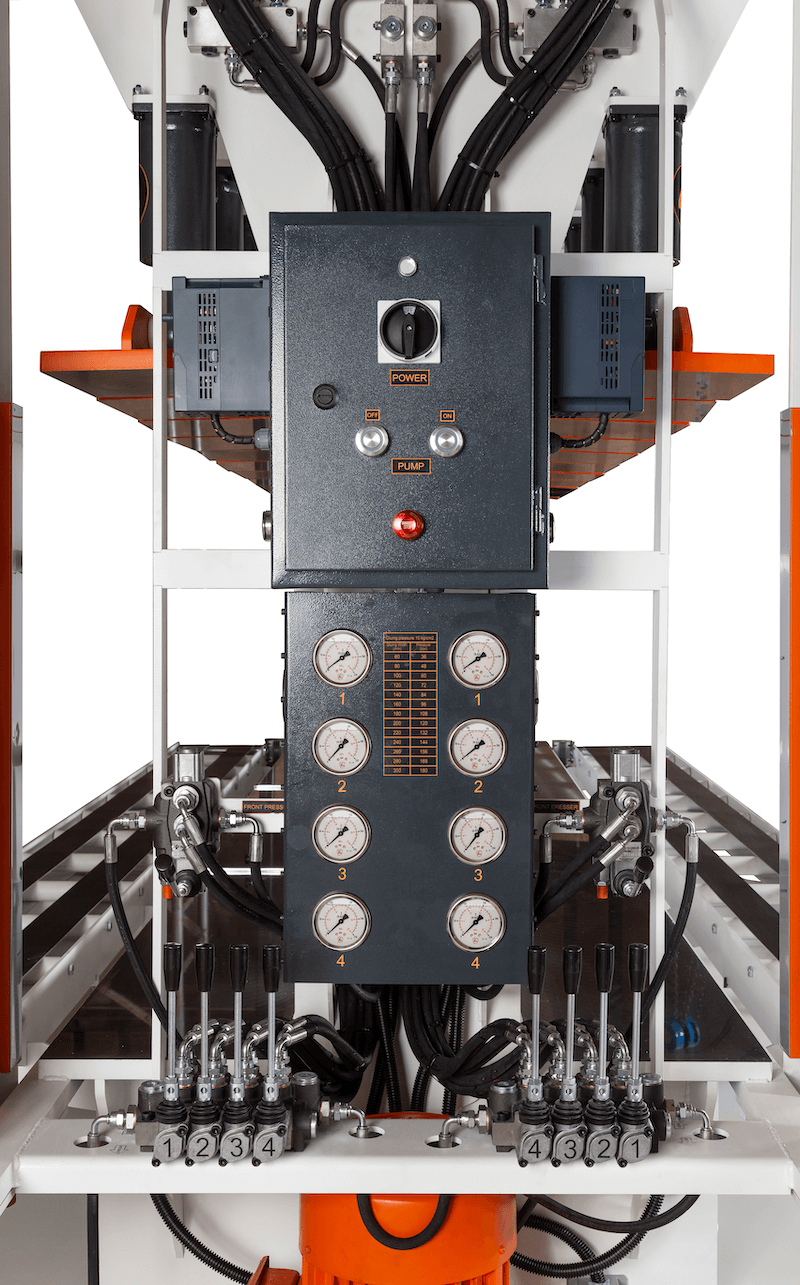

Multiple independent gluing cycles in combination with stop valve on each cylinder - This feature enables users to turn off and on any desired cylinder, which gives users maximum flexibility in gluing a variety of different lengths of flooring on a single press.

All of the pressing plates are self-aligning! This feature enables users to compensate for any imperfections in the prepared material and ensure an even distribution of pressure, thus achieving the great quality of the gluing process.

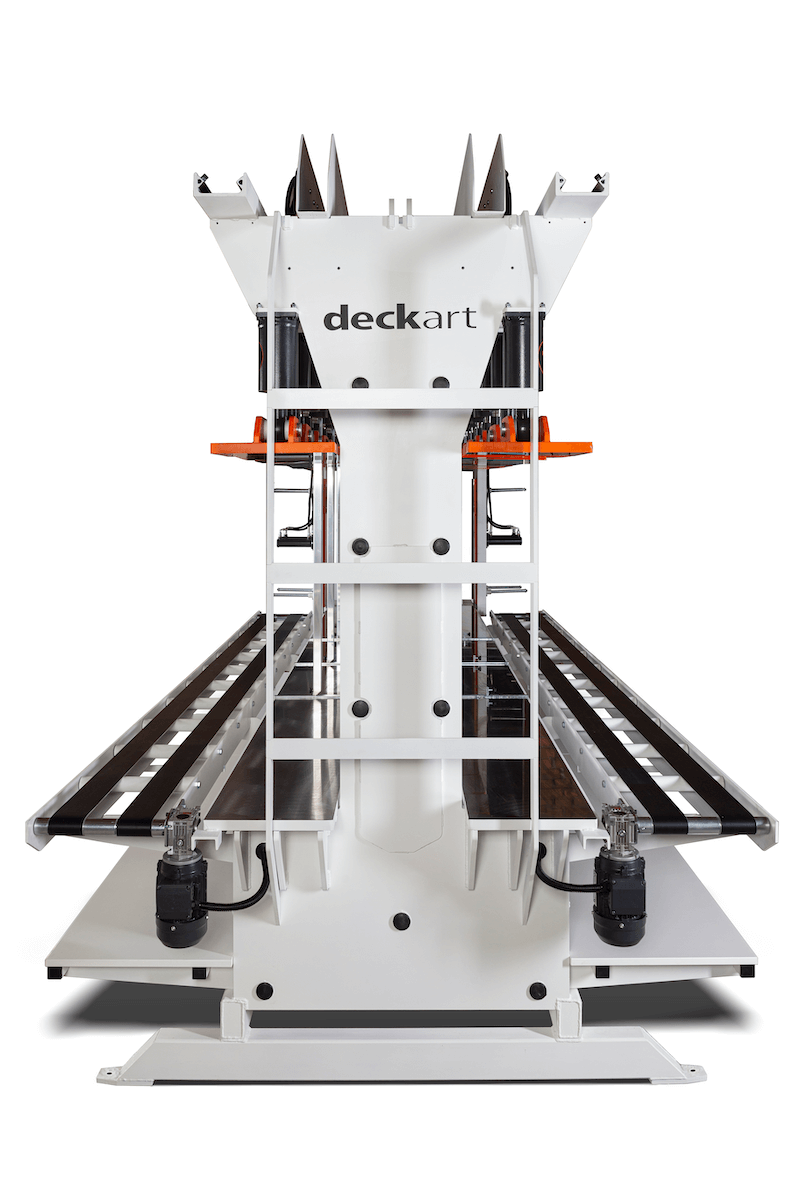

All of the presses are equipped with a motorized conveyor system - for delivering the material from the glue spreading machine to the working spot on the press. The transport speed of the material is digitally controlled.

Specially designed, adjustable back supports will keep the material centered for even pressure distribution, this gives you maximum flexibility when gluing different widths of flooring on a single press.

Powerful hydraulic front-aligning beams will keep the material straight and stable during

the gluing process.

Technical parameters of our standard models:

CP 300/2500 model

- Max gluing width310 mm

- Max gluing length2560 mm

- Max gluing height800 mm

- Working height800 - 850 mm

- No of pressing cylinders (total)16 pcs

- No of pressing cylinders per cycle4

- No of independent pressing cycles4 cylinders x 4cycles

- Pitch between pressing cylinders320 mm

- Each cylinder has its own stop valveYes

- Single stroke80 mm

- Single cylinder pressure9.100 kg

- Cylinder pressure in total145.600 kg

- Max working pressure (For 200 mm width)14 kg/cm2

- Max working pressure (For 300 mm width)10 kg/cm2

- Pressing plate dimensions300mm x 290mm

- Pressing plate typeSelf Aligning!

- No of front aligning beams4 pcs

- Front beams typeHydraulic

- Front Beam PressureUp to 1000 kg

- Max system pressure18 Mpa

- Motorized material transfer conveyorYes, on both sides, independent

- Speed of material transportUp to 30 m/min

- Speed regulation of transfer conveyorYes, both sides, independent

- Power of hydraulic pump5.5 kW (1 pc)

- Power of motor for transportation2x0.35 kW – geared

- Voltage3x400v/50 Hz

- Electricity protectionIP 54

- WeightCca 3.300 kg

- Overall DimensionsCca (l)3405mm x (w)1550mm x (h)2400mm

CP 300/3800 model

- Max gluing width310 mm

- Max gluing length3840 mm

- Max gluing height800 mm

- Working height800 - 850 mm

- No of pressing cylinders (total)24 pcs

- No of pressing cylinders per cycle4 cycles x 4 cylinders and 4 cycles x 2 cylinders

- No of independent pressing cycles8

- Pitch between pressing cylinders320 mm

- Each cylinder has its own stop valveYes

- Single stroke80 mm

- Single cylinder pressure9.100 kg

- Cylinder pressure in total218.400 kg

- Max working pressure (For 200 mm width)14 kg/cm2

- Max working pressure (For 300 mm width)10 kg/cm2

- Pressing plate dimensions300mm x 290mm

- Pressing plate typeSelf aligning!

- No of front aligning beams4 pcs

- Front beams typeHidraulic

- Front Beam PressureUp to 1000 kg

- Max system pressure18 Mpa

- Motorized material transfer conveyorYes, on both sides, independent

- Speed of material transportUp to 30 m/min, adjustable

- Speed regulation of transfer conveyorYes, both sides, independent

- Power of hydraulic pump5.5 kW (1 pc)

- Power of motor for transportation2x0.35 kW – geared

- Voltage3x400v/50 Hz

- Electricity protectionIP 54

- WeightCca 5000 kg

- Overall DimensionsCca (l)4420mm x (w)1740mm x (h)2510mm

.png)

.png)

.png)